Water Heater Sacrificial Anode: What is Sacrificial Anode and When to Replace it?

What is a sacrificial anode?

The sacrificial anode is a metal piece attached to the inside of the tank that gives itself up by slowly reacting with oxygen and corroding first, over time. The metal inside the water unit stays safe. This is known as a redox reaction and simply transforms your hot water tank into a type of cell. When your hot water system corrodes the water may be red or brown in colour.

Sacrificial anode is an important component of hot water systems, providing essential protection against corrosion. They are designed to be “sacrificed,” meaning that they will corrode and dissolve before any of the other components in the system.

Regular maintenance will extend the life of your water heater

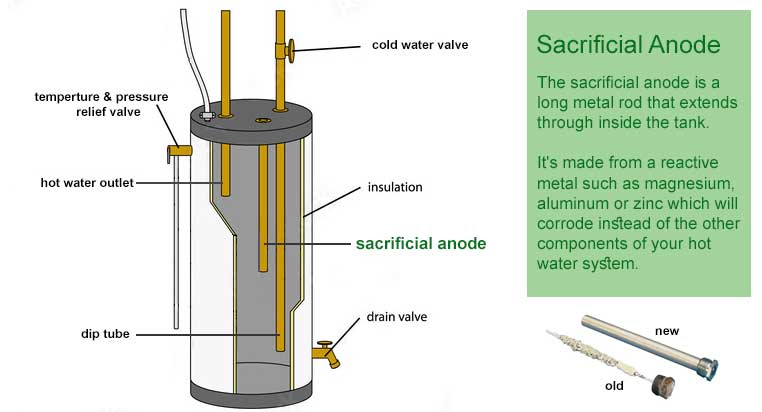

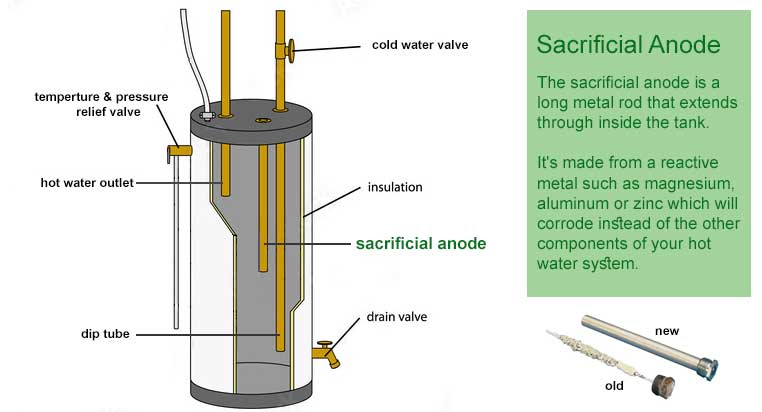

The sacrificial anode is a long metal rod that extends inside the tank. It’s made from a more reactive metal such as magnesium, aluminium or zinc which will corrode instead of the other components of your hot water system. It attracts particles of iron, limestone or other minerals present in the water through an electrochemical process and corrodes in place of the tank.

A sacrificial anode should be installed during installation or repair of all hot water systems – whether they’re residential or commercial – in order to provide adequate protection against corrosion damage. Sacrificial anodes come in different shapes and sizes and can be fixed onto many different types of heating systems including gas boilers, oil boilers, immersion heaters, solar heating systems and air source heat pumps. The higher level of galvanic protection offered by sacrificial anodes means that these systems will last longer and require less maintenance than those without them installed.

How does sacrificial anode prevent corrosion?

The anode is either made of zinc, magnesium or aluminium. It runs electrons to the inside metal surface which acts as the cathode. The presence of water in contact with the anode creates a current that draws electrons to the inner lining. The anode is slowly consumed while the cathode, or inner metal lining gains electrons and remains safe. This requires no added power input as the metal anode and cathode in water creates an electrochemical reaction. This is also known as an oxidation-reduction reaction.

Overview of the process:

- The anode is placed inside the hot water tank.

- The anode releases electrons, which are then picked up by other metals and act as a protective shield.

- The anode corrodes or is consumed.

- The metal of the sacrificial part is oxidized or becomes rust.

- The electrons are added to the cathode, or inner metal lining.

- The inside of the hot water system is safe as the anode sacrifices itself.

How do you replace a hot water system anode?

Hot water system anode replacement is a needed maintenance task that ensures the longevity and efficiency of your water heater. Here’s a detailed, step-by-step guide to help you successfully replace the anode in your hot water system:

Materials and Tools You’ll Need:

- Replacement anode rod (appropriate for your water heater type)

- Pipe wrench or socket set

- Teflon tape

- Garden hose

- Flathead screwdriver

- Bucket or drain pan

- Pipe sealant (if required)

- Step 1: Turn Off the Power

Before starting the anode replacement process, ensure the power supply to your water heater is turned off. For electric water heaters, switch off the circuit breaker. For gas water heaters, set the thermostat to the “Pilot” position. - Step 2: Locate the Anode Rod

Identify the location of the anode rod on your water heater. The anode is typically located on the top of the water heater and is accessible through a hex head fitting. - Step 3: Drain the Tank

Attach a garden hose to the drain valve at the bottom of the water heater. Place the other end of the hose in a suitable drainage area (floor drain or outdoors). Open the drain valve and allow the tank to drain completely. - Step 4: Remove the Old Anode Rod

Using a pipe wrench or socket set, carefully loosen and remove the old anode rod from the water heater. If the anode is difficult to loosen, you can use a cheater bar on the wrench for extra leverage. - Step 5: Inspect and Clean the Tank

While the tank is draining, take a moment to inspect the inside for sediment or debris. Use a flashlight to check for any signs of corrosion. If necessary, flush the tank with water to remove sediment. - Step 6: Apply Teflon Tape

Before installing the new anode rod, wrap the threads with Teflon tape. This helps create a tight seal and prevents leaks. - Step 7: Install the New Anode Rod

Carefully thread the new anode rod into the hex head fitting at the top of the water heater. Use a pipe wrench or socket set to tighten the anode securely. Be cautious not to overtighten, as this may damage the threads. - Step 8: Refill the Tank

Close the drain valve and disconnect the garden hose. Turn on a hot water faucet in your home to allow air to escape as the tank refills. The tank is full once a steady stream of water flows from the faucet. - Step 9: Turn On the Power

For electric water heaters, restore power by flipping the circuit breaker back to the “On” position. For gas water heaters, set the thermostat to your desired temperature. - Step 10: Check for Leaks

Carefully inspect the area around the newly installed anode rod for any signs of leaks. If you notice any leaks, slightly tighten the anode or use pipe sealant on the threads.

Congratulations! You’ve successfully replaced the anode in your hot water system, contributing to your water heater’s overall health and efficiency. Perform this task regularly to ensure continued protection against corrosion and extend the lifespan of your hot water system.

How often should a sacrificial anode be replaced?

The frequency of replacing anode in hot water system varies depending on its type, location, and usage. Generally speaking, it is recommended to replace the anode every three to four years. This timeline can be shortened if the tank experiences high levels of hard water or other forms of mineral build-up which can erode the anode’s effectiveness. Additionally, if the water heater is located in an environment where temperatures rise and fall frequently, this may also lead to more frequent replacement requirements.

To determine when a hot water system anode replacement is needed, it is important to inspect it regularly for signs of wear and deterioration. If corrosion has begun to affect the metal in any way or if there are significant changes to its shape or size, then it is time to replace the anode as soon as possible. This will help prevent further damage from occurring within the water tank and ensure that all necessary safety measures are taken in order to protect its inhabitants from potential hazards.

It is also a good idea to flush out sediment and debris that has built up inside the tank once every few months in order to increase the lifespan of both the sacrificial anode and your water heater itself. Doing so will help reduce mineral build-up which can accelerate corrosion of the anode over time. In addition, regular maintenance should include replenishing electrolytes through rebalancing treatments which are designed specifically for this purpose.

Overall, taking proactive steps such as performing routine inspections and maintenance tasks will help extend your sacrificial anode’s lifespan so that you don’t have to worry about replacing it too often or unexpectedly early. That being said, depending on individual circumstances certain tanks may require replacement more frequently than others so it is always best practice to stay mindful and check up on your water heater regularly.

To book hot water service, call our team today! We’ll be happy to help!

Call 0474 318 136

Or fill in the form below and we’ll call you back.